The Best Sandblasting Service

Serving Southern New Jersey For Over 30 Years

Contact Us Today

Using Mother Nature to Improve Surfaces

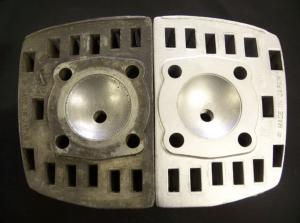

Sandblasting, also called abrasive blasting, is where solid particles (often sand) are blasted by compressed air to smooth, shape, or clean a surface, often concrete. By using this method, the surface is cleaned of contaminants, pollutants, dirt, debris, grime, rust, and other surface items that just don’t belong without damaging the actual surface. From preparing surfaces for painting to removing rust and other existing coatings, sandblasting services are extremely useful in many industries. DJ’s Painting serves southern New Jersey, Pennsylvania, and Delaware with sandblasting services that not only are effective, but also are environmentally-friendly. Contact us today for a free estimate!

Benefits Of Sandblasting In Southern New Jersey

- Environmentally-friendly

- Efficient

- Allows for surface profiling

- Effective

- Versatile

- Removes rust

- Safe

- And so much more!

DJ's Painting can offer your facility more than just industrial painting. DJ's Painting can offer systems that will keep hot surfaces cool to the touch, saving energy costs for your business. Contact DJ's Painting today to find out about this system and other options like floor coatings to have your facility running and looking its best.

We are certified applicators of the concrete protector floor coating systems known as the Perma-flex system. We also work with several other manufacturers of standard high-quality epoxy and urethane floor coatings and stains. Whether you need garage door coatings or coated shop floors, we have what you need.

DJ's Painting has been South Jersey's home painter since 1986. Having painted thousands of homes in New Jersey including log cabin staining, DJ's Painting is the only choice when you want your home to look brand new again. We have the experience needed to get the job done right on every house painting project.